Denver, CO

Architect: C.W. Fentress and J.H. Bradburn Associates

Area:

377,000 Sq.Ft.

City and County of Denver

1995 Completion Date: N/A

Awards

Modern Airport Created with Modern Structural Engineering

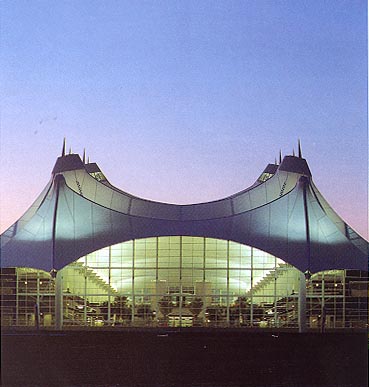

In 1989, Colorado’s Stapleton International Airport turned 60 years old and faced operational challenges that come with age. Fortunately, plans to build an entirely new and thoroughly modern Denver International Airport were already under way. Severud Associates’ design of the fabric roof, steel and glass walls, and fabric curbside canopies for the Jeppesen Terminal created a building with an equally modern—and dramatic—appearance.

Cutting Edge Analysis Results in Timeless Design

The airport’s most notable and acclaimed feature is the ultra-thin, PTFE-coated fiberglass fabric roof, which rises and falls in peaks and valleys that mimic the surrounding Rocky Mountains. Severud Associates used sophisticated non-linear analysis software—developed in-house—to design a tensile membrane system consisting of an outer and inner layer. The outer layer carries snow and wind loads while the inner layer creates an insulating air gap and diffuses light.

Expansive Roof Carries Heavy Loads with Style

The entire project uses almost one million sq ft of fabric while the outer membrane alone employs six miles of cable. To account for the potentially harsh weather in Colorado—heavy snow and strong winds—scale models were tested in a boundary layer wind tunnel and a water flume wind and snow simulator. Severud Associates used the resulting wind and snow drift distributions to develop dozens of load cases for the non-linear analysis of the roof and canopy membranes.

Ridges and Valleys Mimic Nearby Rocky Mountains

Pairs of masts, spaced 150 ft transversely and 60 ft longitudinally, create the peaks of the tensile membrane. Masts are 88 ft high typically; at roughly third points longitudinally, two pairs of masts are 104 ft high. The high mast tops include skylights for additional natural lighting. Cables span from mast to mast and 90 ft each side to form the ridges. Spaced at 60 ft between the pairs of masts, cables arch across the 210-ft width of the terminal to form the valleys.

Cables and Struts Anchor Membrane

Catenary cables connecting the ends of the ridge and valley cables create the scalloped edge of the membrane. The cable end nodes are in turn supported by an extensive system of off-membrane cables and struts, anchored to the conventionally framed roofs that surround the Great Hall on the east, west, and north sides and on an exterior plaza on the south side that was added as part of a later redevelopment and for which Severud made modifications.

Delicate Steel- and Cable-Supported Windows Provide Ample Light

A full-width, 60-ft tall glass wall encloses the south end of the terminal, supported by tubular steel masts with cable stays, which cantilever from the floor. A secondary system of mast cables and a lenticular horizontal cable truss provide additional stiffness and load redistribution. The north end is enclosed by a similar glass wall of roughly half the height. Along the sides, tubular cable-stayed masts form clerestory windows between the low roof and the fabric membrane.

Curbside Canopies Offer Graceful Welcome

Departing passengers are welcomed on the east and west sides of the terminal by tensile membrane canopies, each 880 ft long and supported by a row of large-diameter pipe masts, spaced at 30 ft, which cantilever from the parking structure below it. Three pipe struts branch from the masts, one upwards, one forward, and one back; ridge cables connect the strut ends. Between the masts, valley cables anchored to the parking structure create a saw-toothed profile, like the roof.

Conclusion

Severud Associates has long been at the forefront of providing innovative and economical structural engineering services for airport projects, of which Denver International Airport is a prime example. In the 1950s, the firm designed the American Airlines Terminal at Idlewild Airport—now known as JFK International Airport—and 50 years later engineered its replacement. The tradition continues with design of the new Terminal 6, also at JFK International Airport.